Hydrochloric Acid Solutions

At a glance

Chlorine is used as an oxidizing agent in several organic processes and hydrogen chloride is often generated as a by-product or co-product. The recovery of chlorine from hydrogen chloride or hydrochloric acid has several advantages:

- General commitment in terms of sustainability, careful use of resources and therefore ecological responsibility.

- Business is made independent from chlorine and hydrochloric acid prices.

- Avoids the need to develop traditional chlor-alkali plants with significantly higher investment costs.

- Interesting for regions with high chlorine demand or excess caustic soda (NaOH); use of a chlor-alkali plant would not be expedient due to further NaOH production in saturated markets.

- Eliminates the risks of chlorine transports (as a further alternative).

- No costs related to hydrochloric acid neutralization or disposal.

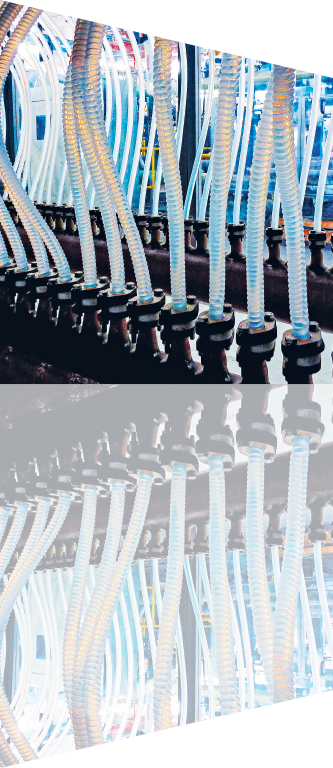

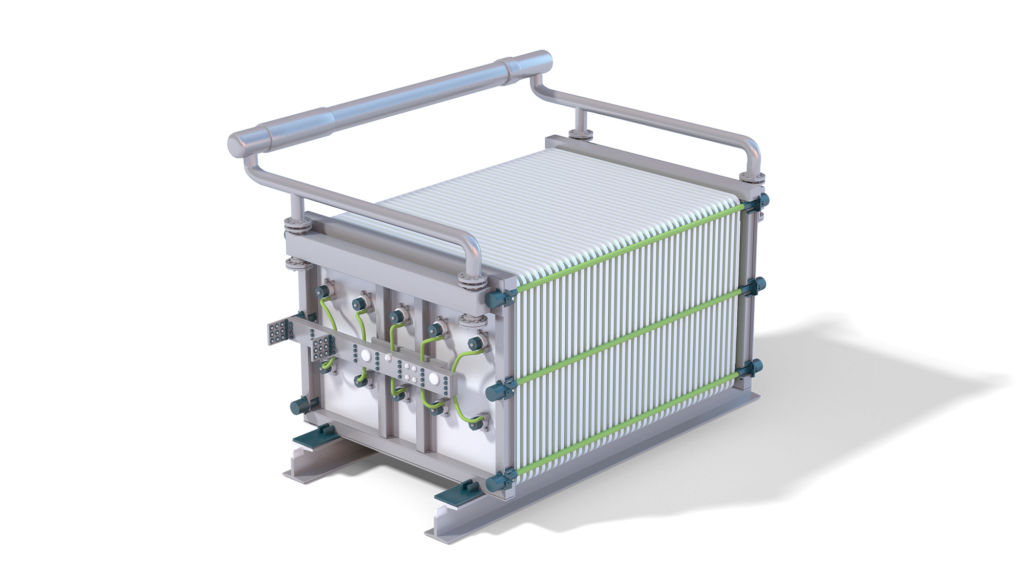

Membrane electrolyzer technology using oxygen-depolarized cathode (ODC)

The ODC (oxygen-depolarized cathode) process cuts energy consumption by about 30% compared with conventional processes. This reduces the indirect carbon dioxide emissions involved in production, accordingly. The ODC process does not produce hydrogen.

- Energy savings by up to 30% compared to diaphragm electrolysis.

- No unwanted H2 production.

- Sustainable use of resources which takes into account environmental responsibility.

- Wide and flexible plant operating window makes it easier to adapt to the needs of MDI/TDI processes.

- Electrolyzer design ensures optimal maintenance flexibility and facilitates potential capacity increases.

- High robustness and durability under corrosive conditions.

- Proven design with bipolar titanium alloy elements in a filter-press-type bipolar electrolyzer

- Automatic control of hydrochloric acid feed concentration

- High quality chlorine

- Operation pressure: 200 to 240 mbarg

- Wide range of HCl feed concentration

The figures above are to be understood as ‘expected values’ and may vary depending on operating conditions.

Diaphragm electrolyzer technology

Our diaphragm technology produces chlorine gas on the anode side and hydrogen on the cathode side – the ideal choice if you also need hydrogen. The process was developed jointly by the former Hoechst AG and Bayer AG as well as thyssenkrupp nucera®. The collaboration between Covestro and thyssenkrupp nucera continues today.

- Produces H2 and does not need an O2 feed.

- Sustainable use of resources which takes into account environmental responsibility.

- Easily adaptable to the needs of related production processes.

- Electrolyzer design ensures optimal maintenance flexibility and facilitates potential capacity increases.

- High robustness and durability under corrosive conditions.

- Bipolar graphite electrode separated by a special PVC or PVC/PVDF diaphragm

- Individual cell elements are assembled similar to a filter-press-type bipolar electrolyzer

- Electrodes are provided with a large number of vertical slots

- Electrodes are fitted into frames made of synthetic material resistant to hydrochloric acid and chlorine

The figures above are to be understood as ‘expected values’ and may vary depending on operating conditions.

Areas of application

Toluene diisocyanate plants (TDI)

TDI is used, amongst others, for the production of flexible foam or for manufacturing coatings and adhesives. In addition, TDI material helps make car parts lighter, improving vehicle fuel efficiency and thus saving energy.

Methylene diphenyl diisocyanate plants (MDI)

Recycling of HCI from other sources

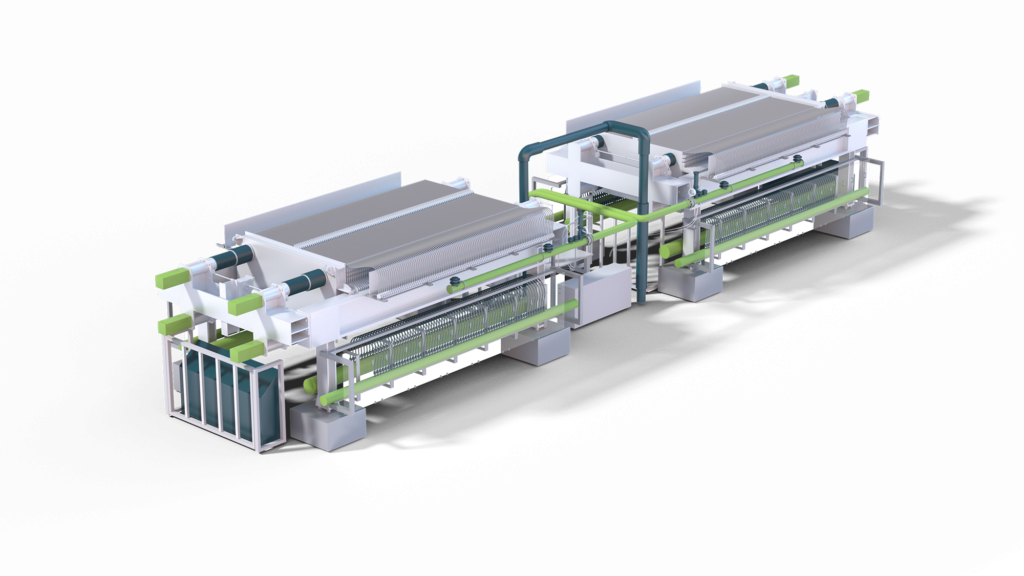

Execution concepts

Compact cell-house design

This largely standardized design is optimized to deliver low total investment costs, minimize space requirements and ensure easy maintenance.

Services at a glance

- Feasibility studies / technology selection

- Project management

- Arrangement of financing schemes

- Financial Guidance based on an intimate knowledge of local laws, regulations and tax procedures

- Environmental studies

- Licensing, incl. basic / detail engineering

- Utilities / offsites / infrastructure

- Procurement / inspection / transportation services

- Civil works and erection

- Commissioning

- Training of operating personnel

- Plant operation support / plant maintenance

- Full service

- Long-term partnership

- Spare parts supply & management

- Upgrade and retrofit

- Revamps

- Digital plant monitoring and optimization (web-based evaluator and remote condition monitoring)

- Consulting

- Service center & field services